ER 316LSi

Alloy ER316LSi Welding data

Weld Process :

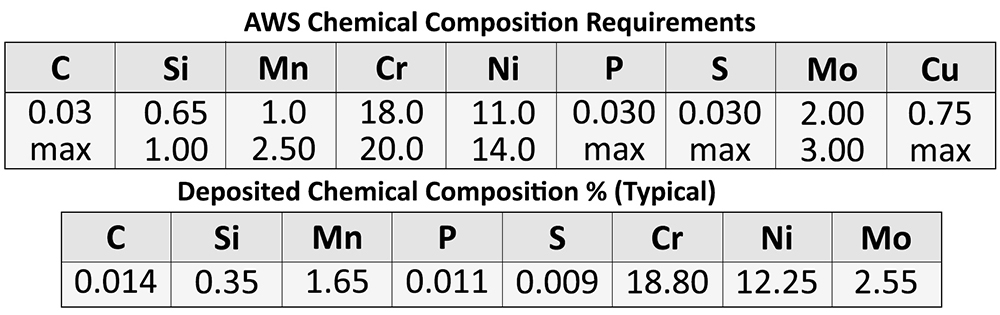

Used for Mig, Tig & Submerged arc Deposited All Weld Metal Properties Data is typical for ER316LSi weld metal deposited by mig using Argon+2% oxygen and Tig using 100% Argon as the shielding gas. Data on Sub-arc is not presented, as sub-arc is dependent on the type of flux used.

Application:

ER-316LSi affords the same characteristics as 316L. The high silican alloys better are stability along with minimal post-weld grinding . The low carbon in the weld metal gives excellent assurance against inter-granular corrosion.

Mechnical Properties (R.T.):

Yield strength > 408 MPa

Tensile strength > 625 MPa

Elongation > 40%

Reduction of area > 67%

Impact value > -196°C (35-58 Joules)

Type of Filler wire

GMAW ” Mig Filler wire”

Diameter Range

0.80-1.6mm 0.030″-1/16″

GTAW ” Tig Process ”

Diameter Range

1.60-4.00mm 1/16″-5/32″

Submerged Arc Welding

Diameter Range

1.60-4.00mm 1/16″-5/32″

Contact:

Tel: +90 232 422 22 22

WhatsApp: +90530 5707355

E-Mails:

info@ankawelding.com.tr

export@anlaweldiing.com.tr

Address:

ANKA KAYNAK ELEKT. SAN. A.Ş.

Küner Mah. Çevreyolu Bulv. 226/A

35470 Menderes/İZMİR/TÜRKİYE